Understanding Oxy Gas Welding

Oxy gas welding, often referred to as oxy-fuel welding, is a versatile and widely-used process in various industries, including manufacturing, automotive repair, and metal fabrication. At the core of this process is an oxy gas welding kit, which provides the tools and gases necessary for heating and melting metal components. This comprehensive guide will explore the components, benefits, usage, and maintenance of an oxy gas welding kit, tailored for both beginners and experienced professionals alike.

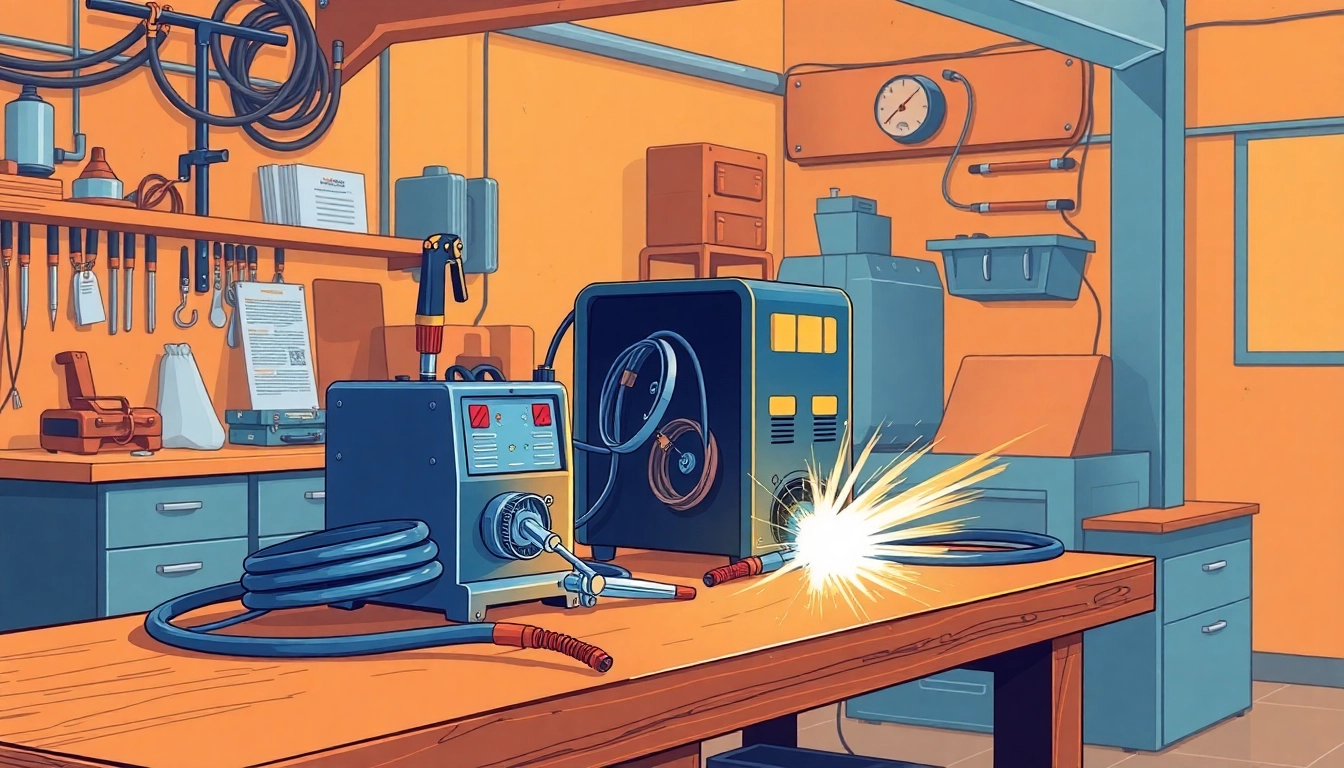

What is an Oxy Gas Welding Kit?

An oxy gas welding kit consists of a set of essential tools and equipment used for welding and cutting metals using oxygen and a fuel gas, typically acetylene. The fundamental principle involves combining these gases to create a high-temperature flame, allowing for the melting of metal materials to create strong joints. A standard oxy gas welding kit includes:

- Oxygen cylinder

- Acetylene cylinder

- Welding torch

- Regulators for pressure control

- Hoses

- Welding goggles and other safety gear

Benefits of Using Oxy Gas Welding

Choosing oxy gas welding offers several advantages:

- Versatility: Oxy gas welding can be utilized for a wide range of applications, from thin sheet metal repair to heavy fabrication.

- Portability: Most oxy gas welding kits are designed to be portable, enabling on-site welding and repair tasks.

- Cost-Effective: Compared to some other welding methods, oxy-acetylene welding is often more economical, particularly in terms of equipment costs.

- Adjustability: The flame can be easily adjusted to different temperatures, allowing for precise control over the welding process.

Applications in Industries

Oxy gas welding plays a crucial role in various industries, including:

- Automotive: Used for repairing exhaust systems, frames, and other body components.

- Construction: Essential in metal frameworks and piping systems.

- Manufacturing: Allows for the fabrication of components in a wide array of products.

- Jewelry making: Used for soldering and creating intricate metal designs.

Components of an Oxy Gas Welding Kit

Essential Tools Included in the Kit

The key components of an oxy gas welding kit are:

- Welding Torch: The primary tool used to combine the gases and deliver the flame to the workpiece.

- Regulators: These devices help to control the flow and pressure of the gases being released from the cylinders.

- Hoses: Flexible tubes that transport gases from the tanks to the torch.

- Cylinders: Containers that store oxygen and acetylene under pressure. It is crucial to use the correct type of cylinders specified for each gas.

- Safety Gear: Protective goggles, gloves, and clothing to safeguard the welder from sparks and harmful gases.

Safety Equipment Required

Safety is paramount in oxy gas welding. Essential safety equipment includes:

- Welding Goggles: These protect the eyes from bright light and UV radiation.

- Gloves: Heavy-duty gloves designed to resist heat and protect the hands.

- Apron: A leather or flame-retardant apron can protect the body from sparks.

- Fire Extinguisher: An accessible fire extinguisher is critical for immediate response to potential fires.

Understanding Gas Cylinders and Regulators

Gas cylinders store oxygen and acetylene, each requiring different handling and storage methods:

- Oxygen Cylinders: These cylinders are usually green in color and must be stored upright. They should be protected from heat sources and physical damage.

- Acetylene Cylinders: Typically, these are maroon or red and must be stored horizontally to prevent the acetylene from dissolving safely into its solvent.

- Regulators: Installed on each cylinder, regulators are essential for controlling gas flow. Proper calibration and regular maintenance ensure safe and effective operation.

Choosing the Right Oxy Gas Welding Kit

Factors to Consider

When selecting an oxy gas welding kit, consider the following factors:

- Intended Use: Determine the applications you’ll be using the kit for, such as automotive repair, metal fabrication, or artistic work, which will influence the type and size of kit you require.

- Portability: If you are frequently traveling to different job sites, consider a lightweight, portable kit that is easy to transport.

- Budget: Establish a budget and review various kits to find one that meets your needs without compromising safety and quality.

- Brand Reputation: Look for trusted brands that offer reliable support and resources, including warranties and customer service.

Budgeting for Your Kit

Creating a budget for your oxy gas welding kit is essential. Factors influencing the cost include:

- Quality of Components: Higher quality materials and components may cost more but are often more durable.

- Type of Kit: Complete kits that include additional accessories, such as multiple nozzles or specialty torches, may have higher prices.

- Brand: Recognized brands may have premiums, but warranties and customer support can justify the investment.

Comparing Popular Kits on the Market

Researching and comparing different kits can provide insights into performance and pricing. Some popular oxy gas welding kits include:

- Victor Oxy-Acetylene Welding Kit: Renowned for quality and durability, this kit is ideal for both heavy and light welding tasks.

- Harris Welding Supplies Torch Kit: Offers a variety of torch sizes suitable for different applications.

- Unimig Oxy Acetylene Welding Kit: A cost-effective solution for beginners, featuring all necessary components for introductory welding tasks.

How to Use an Oxy Gas Welding Kit

Setting Up Your Workspace

Before beginning any welding work, it’s crucial to set up a safe and efficient workspace. Consider the following:

- Ventilation: Ensure good ventilation to prevent the accumulation of harmful fumes and gases.

- Clear Space: Remove flammable materials and clutter from the vicinity of your work area.

- Workbench Height: Set up a stable workbench at a comfortable height to minimize strain while welding.

Step-by-Step Guide to Welding

Follow these steps for effective oxy gas welding:

- Check gas levels in the cylinders and ensure the valves are closed before starting.

- Attach hoses to the regulator and the welding torch, ensuring proper coloring: green for oxygen and red for acetylene.

- Open the acetylene cylinder valve slightly and adjust the pressure with the regulator to the desired setting.

- Light the torch using a flint igniter, then slowly open the oxygen valve to achieve the appropriate flame type (neutral flame is typically best).

- Position the torch at a 45-degree angle to your workpiece and begin welding using smooth, steady motions.

- Once done, turn off the oxygen and acetylene in that order and allow the torch to cool down.

Common Mistakes to Avoid

To ensure safety and quality in welding, avoid the following mistakes:

- Incorrect Flame Settings: Always ensure you’re using the correct flame type for your material. A too-oxidizing flame can weaken welds.

- Poor Workpiece Preparation: Properly clean and align surfaces before welding to ensure a strong bond.

- Neglecting Safety Gear: Always wear appropriate protective equipment to prevent injury.

Maintaining Your Oxy Gas Welding Kit

Regular Maintenance Tips

To maximize the lifespan and performance of your oxy gas welding kit, follow regular maintenance protocols:

- Inspect Hoses: Check hoses regularly for cracks or leaks and replace them as necessary.

- Clean the Torch: Regularly clean the welding torch and its components to prevent clogs.

- Check Valves: Ensure that all valves are functioning properly and check for signs of wear.

Storage and Safety Practices

Proper storage is essential for maintaining the integrity and safety of your kit:

- Store Cylinders Upright: Always keep gas cylinders upright and secured in place to prevent tipping.

- Protect from Heat: Store cylinders in a cool, dry place, away from heat sources.

- Regular Checks: Perform regular safety checks on the storage area to avoid hazards.

Recognizing Wear and Tear

Monitor your equipment for signs of wear and tear. Look out for:

- Worn hoses that may leak gas

- Corroded regulators

- Natural gas build-up around fittings or on the torch itself