Understanding Blow Molding Technology

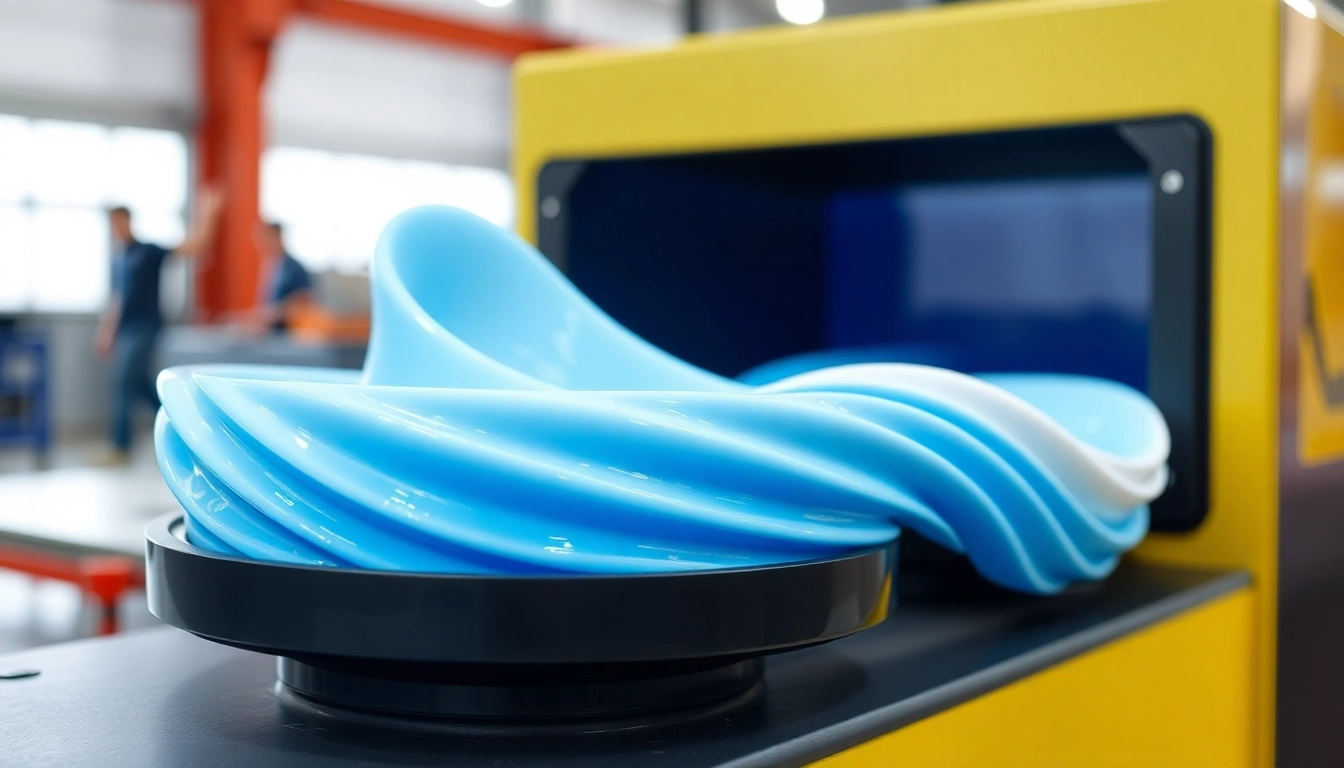

Blow molding is a versatile manufacturing process widely used in producing hollow plastic objects such as bottles, containers, and toys. It is increasingly popular in various industries due to its efficiency and the ability to create complex shapes with a minimal amount of material. As a Blow Molding Machine Manufacturer, it is crucial to grasp the underlying principles and the different types of blow molding technology available.

Types of Blow Molding Machines

Blow molding generally falls into three primary categories: Extrusion Blow Molding (EBM), Injection Blow Molding (IBM), and Stretch Blow Molding (SBM). Each type has unique characteristics that make it suitable for specific applications.

Extrusion Blow Molding (EBM)

EBM is utilized to manufacture hollow plastic products by extruding a continuous tube of thermoplastic, which is then inflated inside a mold. EBM is favored for producing large items such as barrels, containers, and large bottles due to its efficiency in extrusion and molding in a single operation.

Injection Blow Molding (IBM)

IBM combines the processes of injection molding and blow molding. In this process, a preform is created using injection molding, which is then transferred to a mold and blown to form the final shape. This method is ideal for producing highly precise and complex shapes, making it suitable for small items like medical containers or cosmetic bottles.

Stretch Blow Molding (SBM)

SBM enhances the process by stretching the preform both axially and radially, resulting in thinner walls and improved clarity and strength. This method is predominantly used for producing PET bottles for carbonated beverages and is known for its efficiency and lower material usage.

Applications in Various Industries

Blow molding has a diverse range of applications spanning multiple industries:

- Food and Beverage: The assembly of bottles and containers for beverages, sauces, and perishables.

- Pharmaceuticals: Manufacturing containers that require high precision and cleanliness.

- Cosmetics: Producing aesthetically pleasing and functional packaging for personal care products.

- Household Products: Creating a wide array of containers, toys, and home décor items.

Benefits of Choosing Blow Molding

The blow molding process offers several advantages:

- Cost-Effectiveness: High production rates and lower labor costs make it an economically viable option.

- Material Efficiency: Minimal waste during production maximizes material usage.

- Versatile Designs: Capable of producing complex shapes that meet diverse design needs.

- Speed of Production: Rapid processing times allow for large volumes to be produced quickly.

Choosing the Right Blow Molding Machine Manufacturer

Selecting an appropriate blow molding machine manufacturer is crucial for ensuring long-term success and reliability. Several key factors must be considered during this process.

Key Factors to Consider

When evaluating potential manufacturers, consider the following:

- Experience: A manufacturer with a proven track record in the industry demonstrates reliability.

- Technology: Assess whether they use the latest technology for efficiency and improved output.

- Customization Options: Manufacturers that offer tailored solutions can better meet specific production needs.

- Reputation: Look for testimonials, case studies, and references from existing customers.

Evaluating Manufacturing Capabilities

It is essential to evaluate a manufacturer’s capabilities to ensure they can meet your production demands. Inquire about:

- Production Capacity: Their ability to scale operations according to demand.

- Quality Control Processes: How they ensure the consistency and quality of their machines.

- Lead Times: Understand their timelines for production and delivery.

Customer Support and Service

Effective after-sales support is key to maintaining production efficiency. Consider:

- Availability of Spare Parts: Quick access to crucial components can minimize downtime.

- Technical Support: Assess the manufacturer’s capability to provide ongoing technical assistance and training.

- Maintenance Services: Regular maintenance offerings can extend machine life and performance.

Innovations in Blow Molding Machinery

The blow molding industry is continuously evolving. New innovations are enhancing productivity, efficiency, and sustainability.

Latest Technological Advancements

Recent developments include:

- Enhanced Automation: Incorporating robotics for precise handling and operations.

- Smart Technologies: Integrating IoT solutions for real-time monitoring and data analytics.

- Energy-Efficient Machines: Recent models consume less power and provide eco-friendlier options.

Industry 4.0 and Automation

Industry 4.0 principles are reshaping the manufacturing landscape. Advanced technologies allow for:

- Predictive Maintenance: Analyzing data for proactive service scheduling.

- Decentralized Control Systems: Allowing for more adaptive production processes.

- Improved Product Traceability: Enhancing quality assurance and regulatory compliance.

Eco-friendly Manufacturing Practices

As environmental concerns escalate, manufacturers are adopting eco-friendly practices:

- Recycled Materials: Utilizing recycled plastics to reduce dependency on virgin materials.

- Biodegradable Plastics: Innovative materials are being explored for sustainable production.

- Energy Recycling: Machines designed to recycle energy during operation enhance overall efficiency.

Comparing Leading Blow Molding Machine Manufacturers

Several companies stand out in the blow molding machine manufacturing sector. Comparing their offerings can help guide selection.

Market Leaders and Their Offerings

Key players in the industry include:

- Uniloy: Renowned for providing a range of blow molding technologies and superior service.

- Wilmington Machinery: Specializes in high-speed rotary and multilayer machines.

- Jomar Corporation: Celebrated for its innovation in injection blow molding machinery.

- Bekum: Known for its successful H-series of blow molding machines in the American market.

User Reviews and Testimonials

Researching user reviews provides insights into real-world usage experiences. Testimonials regarding:

- Performance metrics and effectiveness of the machinery.

- The support and service provided post-purchase.

- Long-term reliability and maintenance requirements.

Case Studies of Successful Implementations

Specific case studies can illustrate how different manufacturers overcome challenges. Look for examples showcasing:

- Innovative production solutions that increased output.

- Successful implementations of new technologies.

- Steps taken in response to specific market needs or customer requests.

Cost Considerations and Financial Implications

Investing in blow molding technology requires careful cost analysis. Understanding the financial implications is critical for businesses.

Investing in Quality Machinery

Quality machinery may come with a higher initial price but leads to:

- Consistency in product quality.

- Reduced downtime and maintenance expenses.

- Higher production efficiency over time.

Long-term Cost Savings

Consider the long-term financial impact by evaluating:

- Energy and material savings due to efficiency.

- Potential for product diversification with advanced machinery.

- Future-proofing your operations through scalable technology.

Financing Options for Businesses

Many manufacturers provide flexible financing plans to ease the upfront financial burden. Explore options such as:

- Leasing arrangements that help preserve capital.

- Installment payment plans to spread costs over time.

- Special financing offers during trade shows or promotional periods.