Understanding the Basics of the f82 Intercooler

In the world of performance automotive engineering, the f82 intercooler plays a crucial role in enhancing vehicle performance. Understanding its importance starts by defining what an intercooler is and how it functions within an automotive system.

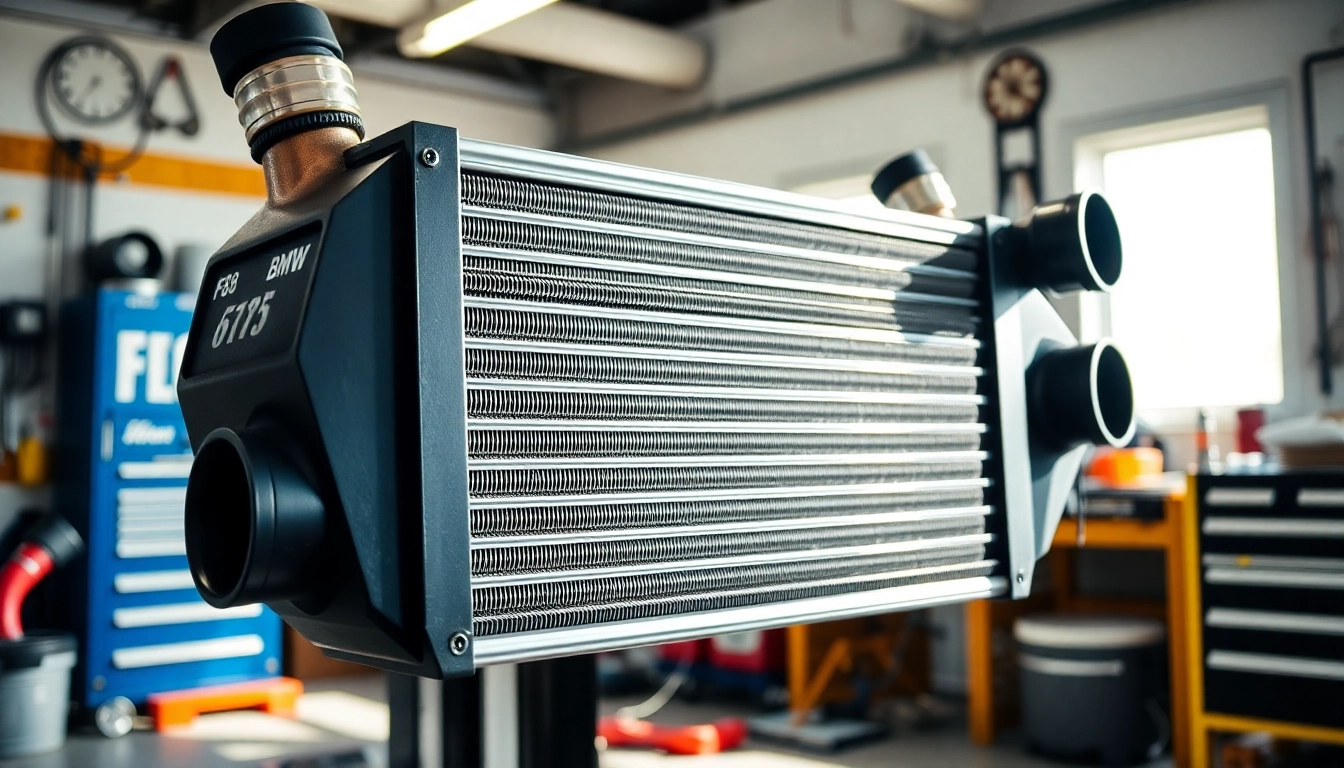

What is an Intercooler?

An intercooler is a heat exchanger used to cool the intake air from the turbocharger or supercharger before it enters the engine’s combustion chamber. By reducing the temperature of the air, the intercooler helps maximize air density, leading to improved engine performance. This ensures that the engine receives a greater amount of oxygen, which is vital for combustion efficiency and overall horsepower.

Importance of Intercoolers in High-Performance Vehicles

High-performance vehicles, particularly those using forced induction systems like turbochargers or superchargers, generate significant amounts of heat during operation. This heat can lead to what is known as “heat soak,” a condition where the intake air temperature rises, reducing the efficiency of the engine. The f82 intercooler mitigates this risk by effectively lowering the intake air temperature, allowing the engine to function optimally without experiencing power losses.

Components and Functionality of the f82 Intercooler

The f82 intercooler typically consists of several key components, including:

- Core: The core is where the actual heat exchange happens, usually made of aluminum for better heat dissipation.

- End Tanks: These help direct air into and out of the core and are often designed to minimize turbulence.

- Mounting Brackets: These provide a secure attachment to the vehicle’s engine bay.

- Inlet and Outlet Pipes: These are essential for connecting the intercooler to the engine and turbocharger.

When a vehicle is equipped with the f82 intercooler, air passes through the core, where it is cooled before entering the engine, thereby increasing efficiency and performance.

Benefits of Upgrading to an Aftermarket f82 Intercooler

While stock intercoolers are designed for everyday driving, upgrading to an aftermarket f82 intercooler can provide significant performance benefits that enhance the driving experience.

Enhanced Cooling Efficiency

One of the most compelling reasons to upgrade to an aftermarket f82 intercooler is the enhanced cooling efficiency it offers. Aftermarket options often feature larger core sizes and more advanced design elements compared to stock units, enabling superior heat dissipation. This efficiency leads to cooler intake temperatures, which is essential for maintaining optimal engine performance during spirited driving or track sessions.

Improved Horsepower and Torque Output

By ensuring that the engine receives denser, cooler air, an upgraded f82 intercooler can significantly increase horsepower and torque output. This translates to improved acceleration and responsiveness, often noticeable in real-world driving conditions. Many enthusiasts report a remarkable boost in power after installation, making it a worthwhile investment for performance-minded drivers.

Reduction of Heat Soak During Performance

Heat soak is a common issue, especially in high-performance driving scenarios where temperatures can rise quickly. An upgraded f82 intercooler reduces the likelihood and impact of heat soak, ensuring that the engine maintains high performance throughout a driving session. With a more effective intercooler, drivers can enjoy consistent power delivery without the detrimental effects of thermal fatigue.

Key Features to Look for in an f82 Intercooler

Choosing the right f82 intercooler involves understanding and evaluating several key features that contribute to performance and functionality.

Core Size and Design

When selecting an intercooler, the core size and design are critical. A larger core typically equates to better cooling capacity because it has more surface area for the heat exchange process. Additionally, consider the flow design; a well-designed core promotes optimal airflow, reducing restrictions that could hamper performance.

Material Construction and Durability

The construction material of the intercooler can greatly affect its durability and efficiency. Most high-performance intercoolers are made from aluminum, which offers a combination of lightweight characteristics and excellent heat conductivity. It’s also important to look for durable construction that can withstand the rigors of high-performance driving and harsh conditions.

Compatibility with Tuning Solutions

Ensure the f82 intercooler you choose is compatible with various tuning solutions. An intercooler that aligns well with aftermarket tuning components not only enhances overall performance but also supports future upgrades. Compatibility is crucial for achieving the desired power gains without running into installation or performance issues.

Step-by-Step Installation Guide for the f82 Intercooler

Installing an f82 intercooler can be a rewarding task for do-it-yourself enthusiasts. Below is a comprehensive guide to assist you in the installation process.

Tools Required for Installation

Before starting the installation, gather the necessary tools, which may include:

- Socket set

- Wrenches

- Flathead and Phillips screwdrivers

- Torque wrench

- Cooling system bleeder kit (if applicable)

- Shop towels and zip ties for cable management

Preparation and Removal of the Existing Unit

Begin by safely raising the vehicle and securing it with jack stands. Remove the front bumper to access the stock intercooler. Disconnect the inlet and outlet pipes and any electrical connections that may be in the way. Carefully unbolt the factory intercooler from its mounting points and remove it from the vehicle.

Installing the New f82 Intercooler

With the old intercooler removed, it’s time to install the new f82 intercooler. First, position the new intercooler in place and secure it using the factory mounting points. Reconnect the inlet and outlet pipes, ensuring a snug fit to prevent leaks. It may be necessary to trim or adjust certain components for a proper fitment. Once everything is in place, carefully reattach the front bumper. After installation, check the connections for any leaks before conducting a test drive.

Performance Metrics and Testing After Installation

After successfully installing the f82 intercooler, evaluating its performance is essential to ensure that the upgrade meets expectations.

Measuring Changes in Intake Temperatures

One of the primary metrics to assess after installation is the intake air temperature. Use an OBDII scanner or a temperature gauge to monitor changes under various driving conditions. A noticeable decrease in temperature compared to the stock intercooler indicates a successful upgrade.

Evaluating Performance Improvements on the Road

Take the vehicle for a test drive, monitoring throttle response and acceleration. Pay attention to how the car feels during hard acceleration and cornering; improvements in power delivery and overall responsiveness should be apparent. A successful installation typically results in a more dynamic driving experience.

Long-Term Maintenance and Care for the f82 Intercooler

To ensure that the f82 intercooler continues to perform at its best, regular maintenance is crucial. Check for leaks in the piping and connections periodically, particularly after high-performance driving. Cleaning the core may also be necessary to prevent blockages from dirt and debris that could affect cooling efficiency. Keeping the intercooler in pristine condition will help maintain the performance benefits derived from the upgrade.